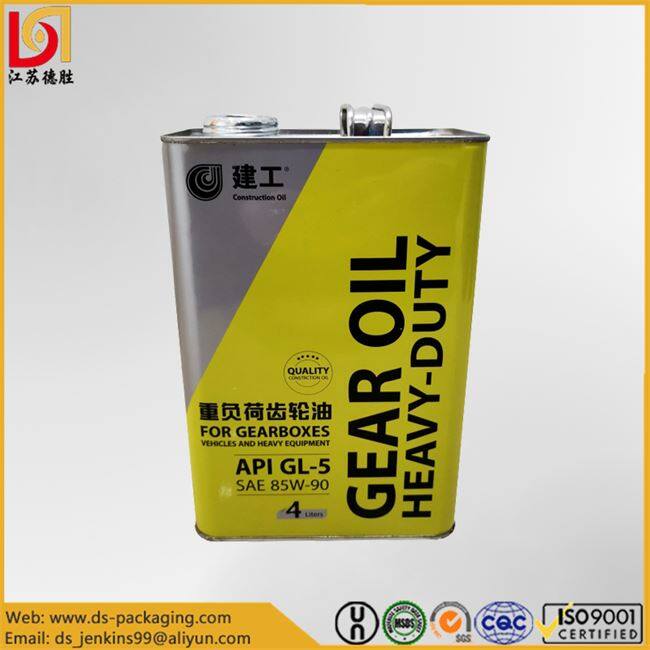

Products Description

The 4l F Style Can is ideal for storing and carrying liquids and chemicals. This 4l F Style Can is commonly used for motor oil, engine oil, lubricating oil, grease, paint, latex, brake fluid, and other applications, and it comes with a variety of covers. The rectangular can body is both elegant and impressive. It can be compactly packed for convenient transport and cost savings.

Specification

|

Material |

Prime tinplate |

|

Capacity |

4 Liter |

|

Thickness (mm) |

0.23~0.28mm or According to customers' requirements |

|

Size (mm) |

168 (L) x 105 (W) x 260(H) mm, 180 (L) x 105 (W) x 240(H) mm or customized |

|

Outside |

CMYK printing |

|

Inside |

Lacquered with 100% Phenolic epoxy resin |

|

MOQ |

6000pcs for inner coating / external customized printing |

|

Certificate |

MSDS, ISO 9001, UN approved |

|

Sample |

2pcs are free of charge, customers just need to pay for the freight |

|

Customization |

1) sample can for us to copy |

|

Payment |

30% T/T deposit in advance and 70% before shipment or Negotiated Method |

|

Delivery time |

About 25 days after payment and sample confirmed |

Appearance and Structure

1. Shape: This shape, which is generally square or nearly square, allows for more compact storage and transit, increasing space usage.

2. Size: Standard dimensions are 180mm long, 105mm broad, and 240mm high, although items made by different manufacturers may change somewhat.

3. Can cover: The spout cover allows you to easily pour liquid into the can while also controlling the outflow speed and direction. It is ideal for liquid items that must be precisely filled, such as lubricating oil and brake oil; the screw cover has superior sealing performance and can effectively prevent liquid leakage and external pollutants from entering the can.

Features

The 4l F Style Can is made of metal tin or tinplate, which has excellent corrosion resistance and strength, can endure certain pressures and collisions, and efficiently protects the can's contents. At the same time, metal has good barrier qualities that allow it to block light, air, and moisture, extending the shelf life of the can's contents while maintaining performance and quality.

Advantages

1. Durability: Made of sturdy metal, not easily damaged. They can withstand heavy use and are not easily dented or scratched.

2. Versatility: Paint cans are available in a variety of sizes, providing multiple options for storing and transporting different quantities of paint.

3. Convenient storage and transportation: The lid of the paint can is easy to remove, but at the same time it has good sealing properties, effectively preventing paint from overflowing or leaking. This makes them easy to use and transport.

4. Cost-effectiveness: Compared with other types of paint containers, paint tin cans are a cost-effective option.

5. Environmental protection: Paint tin cans are recyclable and can be reused for other purposes, reducing waste and benefiting the environment.

Overall, the advantages of paint cans make them a popular choice for safe and efficient storage and transportation of paint. They are durable, versatile, convenient, cost-effective and environmentally friendly. It also makes a good choice for painters or DIY enthusiasts.

Our Factory

Our factory produces 0.37L-23L tinplate cans and drums, which are widely used in liquid and solid products such as paint/ink/solvent/epoxy resin/paint/glue/powder/pet food/olive oil.

Our factory enjoys the complete shape and design of chemical packaging from Chinese reliable supplier. The packaging produced by our factory meets the United Nations standards (D.G drum), UN 1A2 / Y1.4/100, UN 3A1 / Y1.4/100 and so on.

We have cooperated with some famous brands at home and abroad, such as Jingdong Tuhu, VIC, KCC, Chief, etc., which proves the excellent quality and excellent market value of our products.

Multiple automatic production lines, reliable supply of raw materials, advanced Fuji CMYK four-color printing presses and workers with many years of production experience, form our excellent packaging quality. At the same time, our young creative team can help customers customize the packaging, making the product stand out in the market! If interested, welcome to consult ~

Production Process

1. Prepare raw materials

2. Tin plate incoming quality checking

3. Making a new printing plate

4. Customized printing

5. Printing quality checking

6. Cutting printed tinplate

7. Curling the can body

8. Welding straight seam

9. Shaping into square

10. Top cover & bottom forming

11. Top cover, body and bottom assembled

12. Tightness test

13. Packing

14. Warehouse

15. Shipping